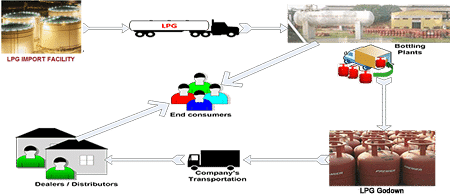

Cylinder Refilling Process

LPG transported from refineries/importers/blenders to the bottling plants in mobile tankers. It is then pumped into the storage tanks installed at the bottling plants with the help of compressors/pumps through the pipelines. LPG is then filled in cylinders through semi-automatic/manual filling guns. Filled cylinders are tested for physical/welding leakage through the tub-test and then the valve/O-ring is checked through leak test device, accurately weighed and then sealed with tamper proof seals before dispatched to the dealers/consumers. Only tested cylinders are stored for delivery. New empty cylinders before filling are passed for air cleaning through purging gun. Quality Control and fire protection systems are also installed at site. Cylinders are not allowed to be thrown or rolled from one point to another and should be handled carefully and safely. All our cylinders are BIS and PESO approved and is periodically tested as per Gas Cylinder Rules.